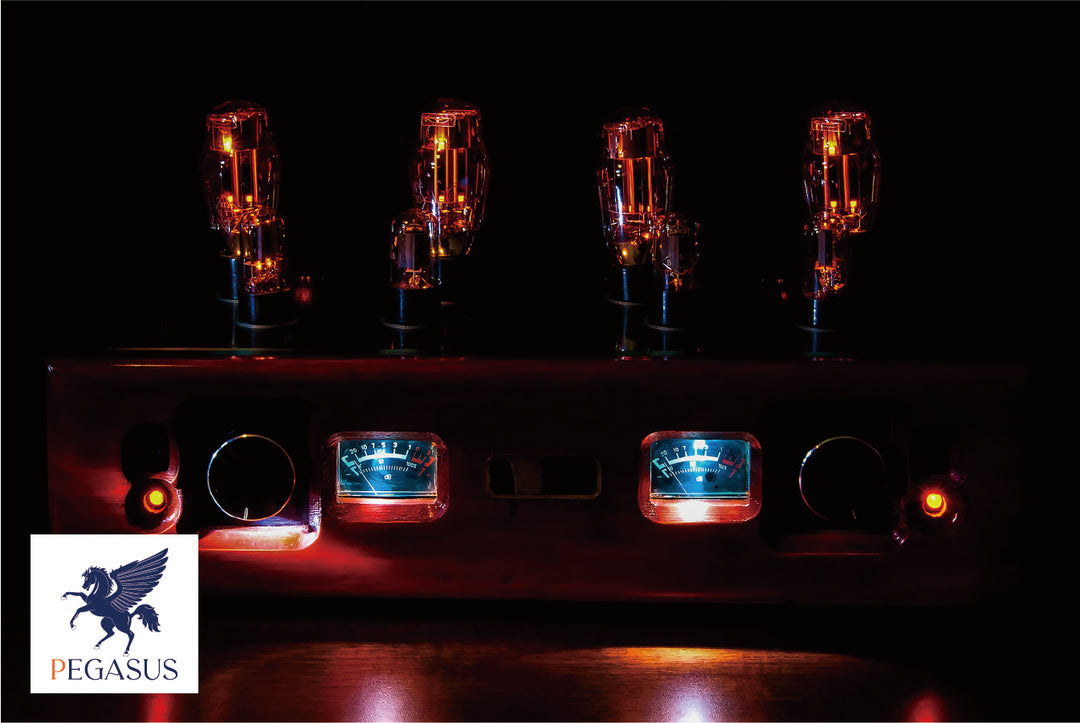

GEC KT66 single power amplifier

We have finished delivering the KT66 amplifier that we have been working on since the end of last year. Recently, there have been Chinese-made KT66s on the market, but the original ball has a really nice style.

The KT66 has long been recognized by ultra-high-end enthusiasts.

The fact that Quord used KT66 instead of KT88 means that KT66 was the sound that the British preferred.

Even in Japan, those who prefer American sound should go for KT88 or 6550.

Those who prefer European sounds will probably go for KT66 or EL37.

Marantz has put all of its heart and soul into the EL34. EL34 is a ball born in Europe. In that sense, it probably has a sound or something similar to the KT66.

I digress, but this KT66 single amplifier was produced in an unusual way. I did everything by hand, including drilling holes in the chassis. It's nostalgic, isn't it? (lol) If you draw a drawing and give it to the contractor,

It takes care of all the most troublesome processing, and it's also beautiful.

So why did I do all the drilling myself this time?

That's because we wanted to deliver a soulful amp to those who own this amp. Chassis punches, hand nibblers, electric drills, hand drills, filers, etc. I was drilling holes even in the middle of the night.

For some reason, it reminded me of making radios and amplifiers when I was a student.

I used to go to Akihabara because it used to be a lively place.

I made this while remembering that.

The work is also difficult, such as processing round holes that do not match the size, square holes, etc., but it is fun to make while recalling the past, and the drilling was almost finished in two days.

Rather than that, it was bigger that the work did not progress with the design.

Industrial design can be a boring amp if it's just right.

On the other hand, I got tired of the design of amplifiers that everyone made, and it boiled down.

It is necessary to protect the basics, and how to express individuality within such restrictions,

The design took about 10 days because I was worried about my troubles.

So, just the other day, the amplifier in the photo was completed.

I also paid attention to the paint on the bonnet.

Since I was an amateur painting it, I made some mistakes, but I was able to paint it to my satisfaction on the second painting, so I was given a break.

Actually, it's been several months since I received the order. . .

I'm glad that the item was delivered safely.

The result was so good that I thought about making one for myself, but when I remembered the chassis processing, I lost my enthusiasm and excitement.

So, when I feel like I'm going to make it, I make it for myself all at once.

Chassis processing is difficult.

Whether it's a manga or a sketch, it's helpful if you draw up a simple drawing and hand it over to the vendor, who will do the work for you. I felt like I was able to figure out what the chassis processing company was doing (laughs).

The owner of this instrument is a big fan of the European sound.

This is the same person from the Shikoku region who delivered the 2A3 amplifier last time.

Recently, we have received many orders from people in Shikoku.

He has a wonderful sensibility, and he won't be satisfied with my sloppy sound production.

Therefore, mass-produced products cannot compete.

It has to be born out of this kind of passion.

Well, I've been asked to make a Siemens Da amplifier, so I guess that's what I'll be making next.

The KT66 has long been recognized by ultra-high-end enthusiasts.

The fact that Quord used KT66 instead of KT88 means that KT66 was the sound that the British preferred.

Even in Japan, those who prefer American sound should go for KT88 or 6550.

Those who prefer European sounds will probably go for KT66 or EL37.

Marantz has put all of its heart and soul into the EL34. EL34 is a ball born in Europe. In that sense, it probably has a sound or something similar to the KT66.

I digress, but this KT66 single amplifier was produced in an unusual way. I did everything by hand, including drilling holes in the chassis. It's nostalgic, isn't it? (lol) If you draw a drawing and give it to the contractor,

It takes care of all the most troublesome processing, and it's also beautiful.

So why did I do all the drilling myself this time?

That's because we wanted to deliver a soulful amp to those who own this amp. Chassis punches, hand nibblers, electric drills, hand drills, filers, etc. I was drilling holes even in the middle of the night.

For some reason, it reminded me of making radios and amplifiers when I was a student.

I used to go to Akihabara because it used to be a lively place.

I made this while remembering that.

The work is also difficult, such as processing round holes that do not match the size, square holes, etc., but it is fun to make while recalling the past, and the drilling was almost finished in two days.

Rather than that, it was bigger that the work did not progress with the design.

Industrial design can be a boring amp if it's just right.

On the other hand, I got tired of the design of amplifiers that everyone made, and it boiled down.

It is necessary to protect the basics, and how to express individuality within such restrictions,

The design took about 10 days because I was worried about my troubles.

So, just the other day, the amplifier in the photo was completed.

I also paid attention to the paint on the bonnet.

Since I was an amateur painting it, I made some mistakes, but I was able to paint it to my satisfaction on the second painting, so I was given a break.

Actually, it's been several months since I received the order. . .

I'm glad that the item was delivered safely.

The result was so good that I thought about making one for myself, but when I remembered the chassis processing, I lost my enthusiasm and excitement.

So, when I feel like I'm going to make it, I make it for myself all at once.

Chassis processing is difficult.

Whether it's a manga or a sketch, it's helpful if you draw up a simple drawing and hand it over to the vendor, who will do the work for you. I felt like I was able to figure out what the chassis processing company was doing (laughs).

The owner of this instrument is a big fan of the European sound.

This is the same person from the Shikoku region who delivered the 2A3 amplifier last time.

Recently, we have received many orders from people in Shikoku.

He has a wonderful sensibility, and he won't be satisfied with my sloppy sound production.

Therefore, mass-produced products cannot compete.

It has to be born out of this kind of passion.

Well, I've been asked to make a Siemens Da amplifier, so I guess that's what I'll be making next.